Introduction

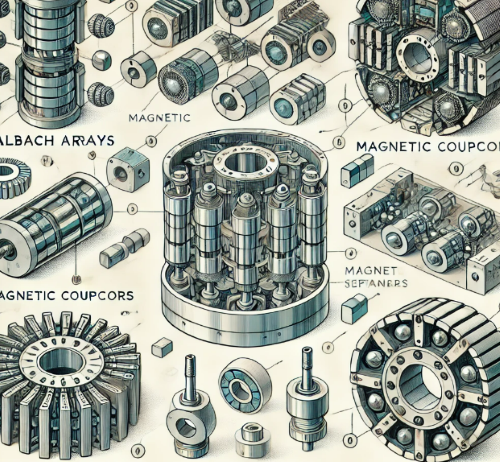

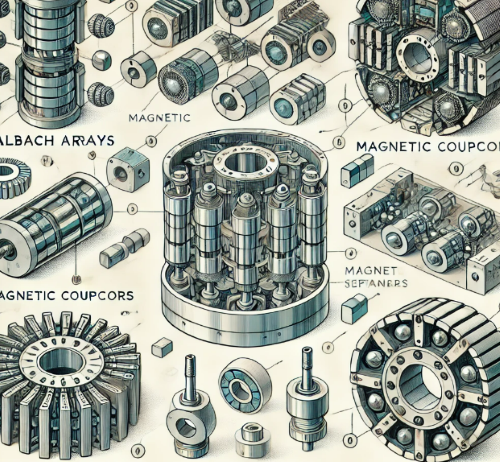

Magnet assemblies play a crucial role in a wide range of industries, each designed to serve specific applications. Understanding the different types of magnet assemblies by their application can help in selecting the right type for your needs. Below is an overview of the most common types of magnet assemblies categorized by their applications.

1. Magnet Assemblies for Motors and Generators

Magnet assemblies are integral to the operation of various motors and generators, including DC motors, AC motors, stepper motors, and wind turbines. These assemblies typically include permanent magnet rotors, stator magnets, and Hall effect sensor magnets. They are designed to generate rotational motion or electrical energy by interacting with the magnetic field in the motor or generator.

2. Magnetic Separation Assemblies

Used extensively in industries like mining, food processing, and waste recycling, magnetic separation assemblies are designed to remove ferrous contaminants from mixtures. These assemblies often employ powerful magnets or magnetic grids to capture magnetic materials, ensuring the purity of the product or protecting downstream equipment from damage.

3. Magnetic Coupling Assemblies

In applications such as magnetic pumps or magnetic couplings, magnet assemblies transfer mechanical force or rotational motion without direct physical contact. This is particularly useful in environments where a hermetic seal is necessary, such as when handling corrosive liquids or in vacuum systems.

Related reading: Magnetic Assemblies 101: Types and Applications

4. Magnetic Lifting Assemblies

Industrial applications that require the lifting and moving of heavy ferromagnetic objects, such as steel manufacturing, shipbuilding, and heavy machinery, rely on magnetic lifting assemblies. These assemblies, often using electromagnets or permanent magnets, provide a powerful and efficient method for material handling.

5. Magnetic Holding and Mounting Assemblies

These assemblies are widely used in clamping, tool holding, door latching, and workbench mounting applications. Magnetic holding and mounting assemblies use magnetic force to securely hold objects in place or serve as temporary fixtures, making them versatile tools in both industrial and commercial settings.

6. Sensor and Measurement Device Magnet Assemblies

Magnet assemblies are at the core of various sensors, including Hall effect sensors, magnetic encoders, and magnetic switches, which detect position, speed, angle, or current. These assemblies are critical for precise measurement and control in automotive, industrial, and consumer electronics applications.

7. Medical and Biotechnology Magnet Assemblies

In the medical field, magnet assemblies are used in applications such as magnetic resonance imaging (MRI), targeted drug delivery, magnetic surgical tools, and magnetic bead separation. These assemblies must be carefully designed and controlled to meet the stringent requirements of medical and biotechnological applications.

8. Magnetic Shielding and Interference Suppression Assemblies

Magnetic shielding assemblies are used in electronic devices to reduce electromagnetic interference (EMI) and radio-frequency interference (RFI). These assemblies protect sensitive circuits and minimize electromagnetic noise between different components or devices, ensuring proper functionality in complex electronic systems.

9. Magnetic Locking and Security System Assemblies

Magnet assemblies are crucial in security systems, including magnetic locks, magnetic sensors, and magnetic switches, used in access control, window alarms, and other safety devices. These assemblies provide reliable and durable solutions for securing properties and protecting assets.

10. Magnet Assemblies for Toys and Educational Tools

Magnet assemblies are also prevalent in the toy and education sectors, used in products like magnetic puzzles, construction toys, magnetic bookmarks, and educational demonstration tools. These assemblies leverage the attractive and repulsive forces of magnets to inspire creativity and hands-on learning among children and students.

Conclusion

Magnet assemblies are engineered to meet the specific needs of their application, optimizing performance, durability, and efficiency. Whether in industrial machinery, medical devices, or educational tools, the right magnet assembly can enhance functionality and reliability, making it an indispensable component in many technologies. Understanding the various types of magnet assemblies by their application is essential for selecting the best solution for your specific requirements. For more information, please check Stanford Magnets