Introduction

Ring magnets, with their unique circular shape and powerful magnetic fields, are used in a variety of applications across different industries. Below are some of the most common uses of ring magnets:

1. Magnetic Bearings

Magnetic bearings are used in high-speed machinery, including turbines, compressors, and flywheels, where minimizing friction is crucial. Ring magnets are often utilized in these systems to levitate rotating parts, eliminating the need for physical contact and reducing wear. By suspending a rotor or spindle in mid-air, magnetic bearings improve efficiency, extend the lifespan of equipment, and allow for smoother operation at higher speeds.

Further reading: The Numerous Shapes of Neodymium Magnets

2. Maglev Trains

One of the most famous applications is in maglev trains (magnetic levitation trains). These trains use electromagnetic systems, often involving ring-shaped magnets, to levitate above tracks, eliminating friction between the train and the rails. This allows for faster travel at higher speeds while reducing energy consumption compared to traditional trains.

[1]

3. Electric Motors and Generators

Ring magnets are often used in the construction of electric motors and generators, where they serve as the core magnetic element to create rotating magnetic fields. They are commonly found in motors used in small appliances, industrial machinery, and electric vehicles. Their compact size and powerful magnetic field make them ideal for providing the necessary torque and power in these applications.

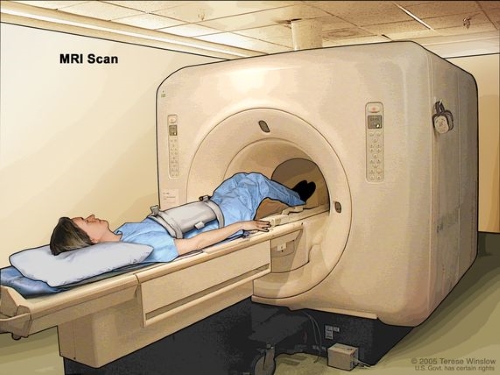

4. Magnetic Resonance Imaging (MRI)

Ring magnets are used in MRI machines, where they generate the strong, uniform magnetic fields needed for imaging. In MRI systems, superconducting ring magnets create a magnetic field that interacts with hydrogen atoms in the body, enabling detailed internal imaging without invasive procedures. The circular shape of the magnets helps ensure that the magnetic field is uniform around the patient’s body.

[2]

5. Magnetic Separators

Ring magnets are used in magnetic separators, which are devices used to separate magnetic materials from non-magnetic ones in industries like mining, recycling, and food processing. These magnets are positioned in a circular configuration to attract and remove ferrous particles from a flow of materials. The shape of the ring magnet helps to maximize the area of attraction and ensure efficient separation.

6. Speakers and Headphones

Ring magnets are commonly used in the design of speakers and headphones to create the magnetic fields that drive the movement of the diaphragm, producing sound. In these applications, the ring magnet is typically placed around a coil of wire (voice coil), and when current passes through the coil, it interacts with the magnet to create sound vibrations.

7. Magnetic Couplings

Magnetic couplings use ring magnets to transmit torque without direct mechanical contact. These couplings are used in pumps, mixers, and other equipment where the need for a sealed, frictionless connection between rotating parts is essential. Ring magnets in the coupling can transmit power between two shafts, even when they are not physically connected, ensuring that there is no leakage or contamination between the two sections.

8. Magnetic Levitation Systems (Non-Transportation)

In addition to maglev trains, ring magnets are used in other magnetic levitation systems, such as magnetic levitation displays and scientific experiments. These systems leverage the levitation capabilities of ring magnets to suspend objects, often used in demonstration devices, education, and research. Ring magnets provide a stable levitation platform due to their symmetrical, uniform magnetic field.

9. Rotating Machinery

In rotating machinery such as motors and turbines, ring magnets are often used as part of the system’s core to generate the required magnetic field for rotation. These applications benefit from the ring magnet’s ability to create a uniform magnetic field, reducing inefficiencies that might arise with irregular shapes. They are also used in systems that require minimal friction to achieve high rotational speeds.

10. Sensors and Encoders

Ring magnets are used in position sensors and rotary encoders to detect the rotation of a shaft or the position of a component. These devices rely on the magnetic field of the ring magnet interacting with a sensor to provide accurate positional data. The circular nature of the ring magnet ensures that the field is consistent around the object being monitored.

11. Magnetic Lifting Systems

Ring magnets are utilized in magnetic lifting devices, where they are used to lift and move ferrous objects in industrial settings. These magnets are used to carry out tasks like moving large metal sheets, lifting heavy machinery, or transporting metal parts in factories. The ring shape helps in applying an even magnetic force across the lifted object, enhancing the lifting capability.

Conclusion

Ring magnets are versatile components found in a wide range of applications. Whether in the realm of high-speed transportation, industrial machinery, medical devices, or consumer electronics, ring magnets continue to play an essential role in enabling cutting-edge technologies and improving efficiency. For various shapes of magnets, please check Stanford Magnets.

Reference:

[1] Maglev. (2024, November 5). In Britannica. https://www.britannica.com/technology/maglev-train

[2] National Cancer Institute (n.d.). MRI. Retrieved November 14, 2024, from https://www.cancer.gov/publications/dictionaries/cancer-terms/def/mri