A magnetic drum separator is an essential device used to separate ferrous materials from non-ferrous ones in bulk materials such as powders, granules, or liquids. This separation process is critical in ensuring the purity of products, improving recycling efficiency, and protecting machinery from damage caused by metal contaminants. Magnetic drum separators are widely used across various industries, including mining, recycling, food processing, and chemical manufacturing, thanks to their effectiveness, durability, and versatility.

How Magnetic Drum Separators Work

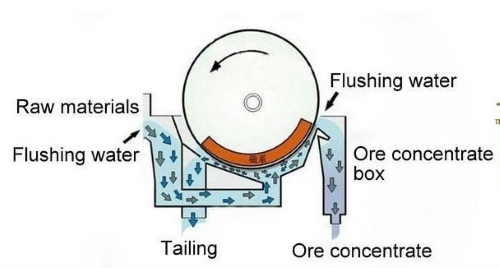

Magnetic drum separators consist of a rotating drum and a magnetic field source. The drum attracts and holds ferrous particles to its surface while non-magnetic materials flow freely past it. The separated magnetic particles are then discharged into a collection area as the drum rotates beyond the magnetic field.

The process begins when materials are fed onto the drum via a chute or conveyor. Ferrous materials adhere to the drum’s surface, while non-ferrous materials are unaffected and continue moving along their original path. The separation ensures the removal of metallic contaminants, improving the quality of the remaining material.

Types of Magnetic Drum Separators

Magnetic drum separators are categorized based on their design and application.

- Permanent magnetic drum separators use powerful permanent magnets, making them energy-efficient and cost-effective. They are commonly employed in recycling and mining industries.

- Electromagnetic drum separators, on the other hand, utilize electromagnets, which allow for adjustable magnetic strength, making them suitable for high-intensity applications.

- In terms of the operating environment, wet magnetic drum separators are designed for use in liquid streams, separating fine ferrous particles from slurries in industries like mining and mineral processing.

- Dry magnetic drum separators, in contrast, handle bulk materials in powder or granule form and are used in food processing, construction, and recycling industries.

Further reading: Something You Should Know About Magnetic Drum Separator

Applications of Magnetic Drum Separators

Magnetic drum separators play a crucial role in a variety of industries.

- In the mining and mineral processing sector, they are used to separate ferrous materials from ores, as well as to concentrate iron ores in both wet and dry processes. This helps improve ore quality and facilitates efficient downstream processing.

- In the recycling industry, magnetic drum separators recover ferrous metals from waste streams, such as shredded scrap, e-waste, and municipal waste, ensuring the purity of recycled materials like glass, plastic, and aluminum.

- The food processing industry uses magnetic drum separators to remove iron contaminants from food products such as grains, spices, and sugar, ensuring product safety and compliance with quality standards.

- In the chemical and pharmaceutical industries, these separators are used to eliminate ferrous particles from powders and raw materials, ensuring the purity and safety of final products. Additionally, in aggregate and construction, they remove metal debris from crushed materials like stone and sand, improving product quality.

Advantages of Magnetic Drum Separators

Magnetic drum separators improve product quality by effectively removing ferrous contaminants, which is especially important in industries like food processing and pharmaceuticals. By eliminating metal impurities, they protect downstream machinery, such as crushers and grinders, from damage, reducing maintenance costs and downtime. In industries like recycling, these separators enhance efficiency by recovering valuable metals from waste streams, contributing to sustainable practices and reducing material waste.

Conclusion

Magnetic drum separators are indispensable in industries requiring the separation of ferrous materials from non-ferrous ones. Their ability to enhance product purity, improve recycling efficiency, and protect machinery makes them a vital tool in industrial processes. Whether used in mining, food processing, or recycling, magnetic drum separators ensure reliable performance, supporting sustainability and operational efficiency across diverse applications. For more information, please visit Stanford Magnets.