NdFeB magnets are crafted from a mixture of neodymium (Nd), iron (Fe), and boron (B), offering a unique balance of strength, durability, and performance. We are going to explore the key properties of NdFeB magnets, explaining how they are used in various industries and applications.

1. Magnetic Strength

One of the most remarkable features of NdFeB magnets is their magnetic strength. These magnets are known for their high energy density, meaning they can produce a strong magnetic field in a relatively compact form. The key metric used to measure the magnetic strength of a magnet is the maximum energy product (BHmax), which is measured in Mega Gauss Oersted (MGOe).

- High Energy Density: NdFeB magnets typically exhibit BHmax values ranging from 33 to 52 MGOe, making them the most powerful permanent magnets available. This high energy density allows these magnets to generate strong magnetic fields while remaining relatively small and lightweight compared to other types of permanent magnets, such as ferrite magnets or Alnico magnets.

- Remanence (Br): NdFeB magnets also show high residual flux density (Br), typically between 1.0 to 1.4 Tesla. This means that once magnetized, they can retain a strong magnetic field for an extended period without requiring any external power.

The combination of high BHmax and high Br makes NdFeB magnets ideal for applications that require significant magnetic force in a compact size, such as in motors, generators, and magnetic assemblies.

2. High Coercivity

Coercivity refers to a magnet’s ability to resist demagnetization. NdFeB magnets have a high coercivity, meaning they can maintain their magnetic properties even when exposed to external fields or physical stress.

- Resistant to Demagnetization: NdFeB magnets have coercivity values typically in the range of 700-1,200 kA/m, depending on the grade of the magnet. This allows them to perform reliably over long periods without losing their magnetic properties, even in harsh conditions.

Due to their high coercivity, NdFeB magnets are commonly used in industries where reliability and consistency are critical, including automotive, aerospace, and electronic applications.

3. Temperature Sensitivity

One of the limitations of NdFeB magnets is their sensitivity to high temperatures. While they exhibit excellent magnetic performance at room temperature, their magnetic properties tend to degrade as the temperature rises. This is because heat can reduce the alignment of magnetic domains, weakening the overall magnetic field.

- Curie Temperature: The Curie temperature (the temperature at which a material loses its magnetism) for NdFeB magnets is typically around 310-400°C, depending on the alloy grade. Above this temperature, the magnet loses its magnetic properties.

- Operating Temperature: The maximum recommended operating temperature for standard NdFeB magnets is typically between 80°C and 200°C. However, there are special high-temperature grades available that can operate at temperatures of up to 220-230°C.

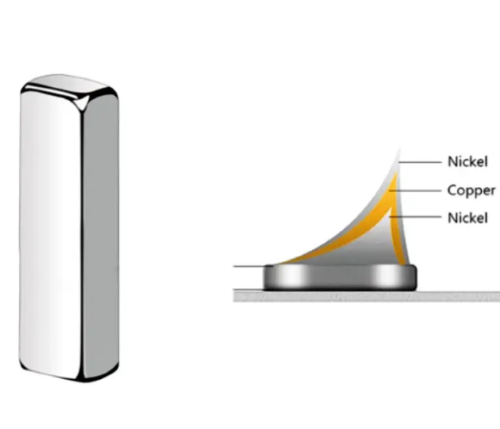

To mitigate this limitation, NdFeB magnets are often coated with protective layers like nickel or epoxy to reduce the impact of temperature fluctuations and environmental exposure.

4. Durability and Hardness

NdFeB magnets are known for their durability and hardness. The combination of iron and boron creates a material that is both tough and wear-resistant, making them suitable for use in demanding environments. They typically have a Mohs hardness rating between 4.5 and 6.5, meaning they can withstand mechanical stresses like wear, friction, and impact better than many other materials.

- Wear Resistance: NdFeB magnets are resistant to wear and abrasion, making them ideal for use in applications like motors, generators, and actuators where continuous motion or high friction may be present.

- Corrosion Resistance: While NdFeB magnets are highly durable, they can be prone to corrosion when exposed to moisture and oxygen due to the iron content. To prevent rusting and deterioration, they are often coated with materials like nickel (Ni), zinc (Zn), or epoxy coatings.

5. Versatility in Manufacturing

Another important property of NdFeB magnets is their versatility in manufacturing. NdFeB magnets can be produced in a variety of shapes and sizes, including disc, cylinder, block, and ring forms, among others. This adaptability makes them suitable for a wide range of applications, from small-scale electronics to large industrial machinery.

- Customization: NdFeB magnets can be customized to meet specific requirements, such as size, shape, and magnetic strength. This flexibility allows manufacturers to design magnet-based solutions for virtually any application.

- Sintered vs. Bonded: Sintered NdFeB magnets are made by pressing and heating powdered NdFeB material to form solid magnets, while bonded NdFeB magnets are created by mixing the powder with a binding agent, allowing for greater flexibility in shape and size. Bonded magnets are typically used in applications where high-volume production and intricate shapes are needed.

6. Cost Considerations

Despite their superior magnetic properties, NdFeB magnets are relatively expensive compared to other types of permanent magnets like ferrite magnets or Alnico magnets. The cost is primarily driven by the use of rare-earth materials like neodymium and the complexity of the manufacturing process.

- Cost vs. Performance: While NdFeB magnets are more expensive, their high performance often justifies the cost, especially in applications where space, weight, and efficiency are critical.

Conclusion

NdFeB magnets stand out as powerful, durable, and versatile permanent magnets available. Their high magnetic strength, resistance to demagnetization, and versatility in manufacturing make them essential in industries ranging from automotive and electronics to renewable energy and medical technologies. For more information, please check Stanford Magnets.