Introduction

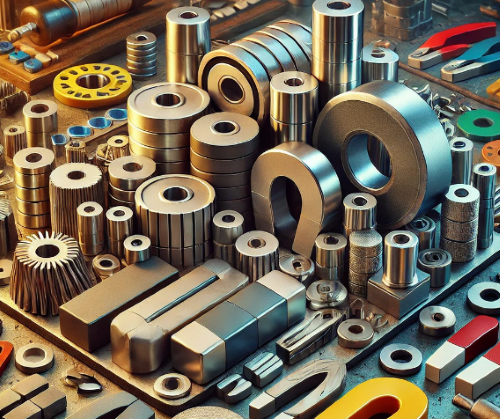

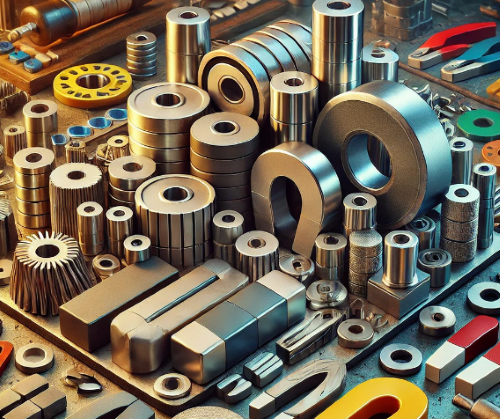

High-strength magnets are crucial components in various industries, known for their ability to generate powerful magnetic fields. These magnets come in different forms, each offering distinct properties that make them ideal for a wide range of applications. Let’s explore their properties, types, and applications, highlighting their importance in modern technology.

Properties of High-Strength Magnets

High-strength magnets are defined by their strong magnetic fields, which arise from materials with high magnetic susceptibility. Key properties include:

- High Magnetic Field Strength: High-strength magnets produce intense magnetic fields, which allow them to attract ferromagnetic materials over greater distances.

- High Coercivity: The ability to resist demagnetization, ensuring that the magnet retains its strength over time and under extreme conditions.

- Temperature Stability: Some high-strength magnets, such as samarium-cobalt, maintain their performance at high temperatures, making them suitable for demanding environments.

- Durability: Many high-strength magnets are corrosion-resistant and maintain their integrity even when exposed to environmental factors such as moisture or chemicals.

- Lightweight: Despite their strength, high-performance magnets are relatively lightweight, which is beneficial in applications where weight is a concern, such as in electric vehicles and aerospace.

Types of High-Strength Magnets

Several types of high-strength magnets are widely used in industry, each with specific advantages and limitations. These include:

1. Neodymium Iron Boron (NdFeB) Magnets:

– Properties: Neodymium magnets are the strongest available permanent magnets. They exhibit high remanence (ability to maintain a magnetic field) and coercivity.

– Applications: Found in electric motors, generators, hard drives, and magnetic fasteners. They are also crucial in renewable energy systems like wind turbines and in consumer electronics like smartphones and headphones.

2. Samarium Cobalt (SmCo) Magnets:

– Properties: These magnets offer high magnetic strength and superior temperature stability. They are resistant to oxidation and are ideal for high-temperature applications.

– Applications: Commonly used in aerospace, military equipment, and medical devices due to their ability to withstand extreme environments.

3. Alnico Magnets:

– Properties: Alnico magnets have a lower magnetic strength compared to neodymium or samarium-cobalt, but they are highly temperature-resistant and have excellent stability over time.

– Applications: Used in sensors, microphones, and electric guitars, where precise magnetic control is required over a wide temperature range.

4. Ceramic (Ferrite) Magnets:

– Properties: While weaker than other high-strength magnets, ceramic magnets are inexpensive and highly resistant to corrosion.

– Applications: Widely used in refrigerator magnets, loudspeakers, and small electric motors due to their low cost and resistance to weathering.

Applications of High-Strength Magnets

High-strength magnets are used in various industries due to their unique ability to provide powerful magnetic forces in a compact form. Here are some key application areas:

1. Electric Motors and Generators:

High-strength magnets are essential in electric motors and generators. Neodymium magnets, in particular, are used in electric vehicle motors, where their lightweight and powerful properties increase efficiency. They also play a crucial role in wind turbines, where they help convert mechanical energy into electrical power.

2. Medical Devices:

In the medical field, high-strength magnets are used in magnetic resonance imaging (MRI) machines, which rely on strong magnetic fields to produce detailed images of the human body. They are also employed in magnetic implants, surgical tools, and hearing aids.

3. Consumer Electronics:

The small size and high power of neodymium magnets make them indispensable in consumer electronics. They are found in smartphones, where they enable functions like wireless charging, and in speakers and headphones to produce high-quality sound.

4. Magnetic Fasteners and Closures:

High-strength magnets are used in magnetic fasteners for secure closures in various products, including bags, furniture, and clothing. Their ability to hold securely yet release easily makes them ideal for such applications.

5. Aerospace and Defense:

The aerospace and defense industries require materials that can withstand extreme temperatures and stress. Samarium-cobalt magnets are often used in jet engines and missile guidance systems, where both high strength and temperature stability are critical.

6. Renewable Energy:

High-strength magnets are at the heart of the renewable energy sector. In wind turbines, they help generate electricity by converting kinetic energy from the wind into electrical energy. Their efficiency in these systems reduces overall energy loss and contributes to more sustainable energy production.

Conclusion

High-strength magnets have revolutionized multiple industries by providing powerful and reliable magnetic forces in compact forms. From neodymium’s unmatched strength in electric motors to samarium-cobalt’s temperature resistance in aerospace applications, these magnets offer a variety of properties suited to specific needs.

As technology continues to advance, high-strength magnets will remain a vital component in driving innovation and improving efficiency in numerous fields. For more super strong magnets and magnet assemblies, please visit Stanford Magnets.